Lately I have been inundated with questions about disinfectant sprays and surface films that offer “residual” or “lasting protection”. I’ve seen plenty of 30 day protection promises and even one offering 90 day protection!

So I’m sharing my reply to these questions with you as I know many people are either concerned or intrigued by these product claims, and will find the questions I raise useful.

First of all I need to point out that I am not a chemist so I cannot comment on the accuracy of individual chemical products claims. Secondly, I’m not saying that scientific evidence of residual efficacy does not exist – it does. But I am questioning whether such laboratory testing has any relationship to a real world situation.

As a high performance cleaning specialist, I can comment on the regulations governing disinfectant claims, and I can raise the practical limitations and considerations that concern me. I’ve also run this by some industrial chemists to ensure my facts are straight.

OK – disclaimers over! Let’s look at whether you can really protect a building surface against COVID-19 for 30 days using a disinfectant film or spray…

Effectiveness of residual disinfectants in the real world

There are now many antimicrobial films and sprays on the market claiming to “bond” with the surface and provide lasting residual efficacy.

However these claims are rarely (if ever) tested in a real life situation and there are many factors that can’t be controlled in your average office, hairdressers or childcare centre. For example:

- The surface may not be suitable for the film or spray product to adhere and coat it fully. Unless the surface is brand new, 100% smooth and impervious, any tiny fissures or undulations could potentially affect its coverage.

- Likewise unless the surface has been deep cleaned first to remove any embedded soil, it could prevent it from adhering properly.

- A general layer of organic matter builds up on the surface throughout the day. This will create a barrier between the film and the virus and overtime reduce its effectiveness.

- As the structure of such chemicals is designed to trap viruses and bacteria, it stands to reason they will trap other organic matter as well. How long will it be before the surface is saturated with dirt and rendered ineffective?

- As these products have a limited life-span, at some point in it’s life-cycle, daily cleaning and usage will start to wear it away and reduce its efficacy.

- Many of these products contain QUATs (Quaternary ammonium compounds) disinfectants. Being positively charged, a layer of QUATs may also attract and build-up a layer of dirt faster than a properly cleaned surface would, creating more of a barrier as already mentioned. Furthermore, this layer could conversely be providing virus particles with a reservoir of organic matter that protects and allows them to remain viable for longer.

- Anionic surfactants contained in many cleaning products may erode or neutralise a QUAT. This applies to after-hours cleaners as well as to the many occupants that now use impregnated wipes on their desks and hands throughout the day.

Practical considerations and questions

Prior to applying an antimicrobial film or spray, you would first need to clear away all objects and deep clean each surface to be coated. This would be very time consuming if repeated on a regular basis – time in my opinion that would be better spent frequently cleaning.

To apply sufficient and effective surface coverage, you would need to be able to control the airflow, and know the correct distance to be hold the spray from the surface, the coverage rate and length of time to spray for and drying time before items could be replaced. I have never seen this type of instruction provided.

Another important consideration is how to remove the film which is so tenaciously bonded to the surface, before reapplying it. If it takes a big effort, using strong chemicals or scrubbing process, this needs to be factored in as well.

So here are some questions you might like to ask suppliers of antimicrobial films and sprays:

- Do they provide detailed technical information about correct application and is this feasible? If yes, does this guidance include:

- Preparation process?

- Suitability of the surface?

- Suitable cleaning agents, tools and techniques?

- Reapplication process?

- Has the product’s efficacy been tested under these real-life conditions? If so, what is the recommended cleaning frequency based on this evidence?

- Do they advocate removing the film before reapplying it? If so, what is the recommended process, chemical and time required to do?

- If they recommend simply reapplying the film on top of the previous layer, could this:

- build up an impenetrable layer that ruins the surface?

- prevent the next layer from adhering or working effectively?

What the TGA Regulations say

In Australia, the Therapeutic Goods Administration (TGA) manages the Australian Register of Therapeutic Goods (ARTG), and the Therapeutic Goods Order 104 for testing anti-microbial agents (disinfectants). Both Residual and Virucidal claims are called “specific claims” under TGA legislation.

All disinfectants claiming virucidal, fungicidal or other efficacy must be approved by the TGA as meeting the requirements of the relevant Therapeutic Goods Order 104, then listed on the ARTG before they may legally make, or imply these claims on disinfectant products sold in Australia.

While the TGA has a list of “Disinfectants for use against COVID-19 in the ARTG for legal supply in Australia” there are no TGA approved testing protocols for Residual Activity, therefore residual activity claims cannot be TGA approved.

Any company claiming residual disinfection against COVID-19 could potentially be in breach of the Therapeutic Goods Act. Technically, any business promoting that such products are being used, such as a premises or service, could also be in breach of the Act.

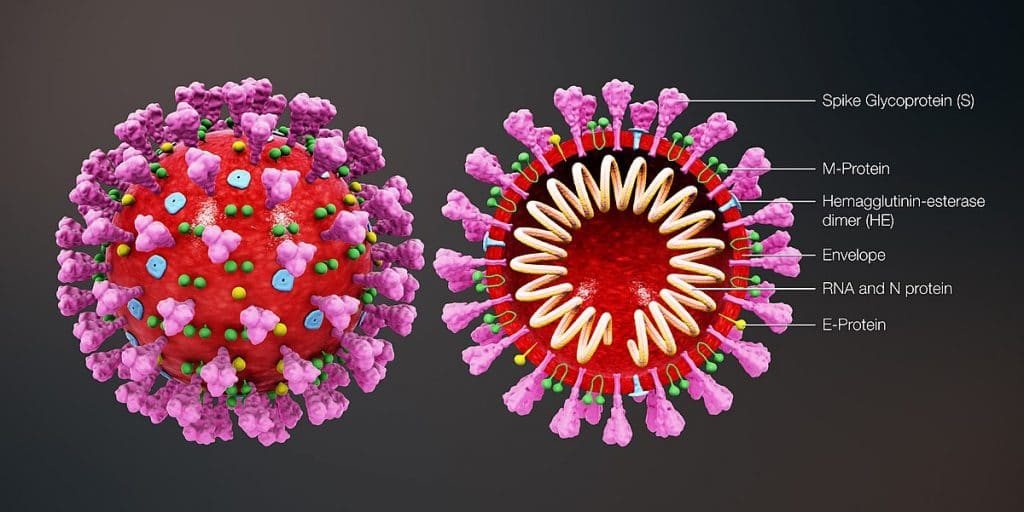

The TGA is actively pursuing companies that contravene their advertising regulations with claims of COVID-19 protection or prevention. Recently the underwear company Lorna Jane were fined $40,000 for claiming their anti-viral underwear “breaks through the membrane shell of bacteria or germs that come into contact with it”.

It would appear that claims made by disinfectant sprays and surface films claiming 30-day protection is not much different.

Don’t create a false sense of security

Whether or not products offering ‘lasting security’ can somehow beat the odds listed above and have evidence to show they can achieve their claims, the reason they are attractive to building managers / owners is because they seem to offer a cheap solution for:

- preventing the spread of coronavirus, and

- giving people confidence they are being protected.

But are they really? I am deeply concerned that they are more likely to be creating a false sense of security that will result in less thorough or less regular cleaning and disinfection of frequently touched surfaces, and less vigilant hand hygiene by building occupants as recommended by the Department of Health and Safe Work Australia.

Cleaning is a science. It is a process, not a quick-fix product.

There are no short cuts to achieving a hygienically clean surface so let’s not sell ourselves short. The stakes are too high not to get this right.

I’d love to hear your thoughts on this important topic and please feel free to share this post with your networks.

Get informed

I urge you to check out our Guide to Cleaning for COVID-19 if you want to know how to comply with Government guidelines and to implement coronavirus prevention and decontamination cleans, to keep your staff safe, and help your customers open back up for business.

Version 4 of this essential Guide contains 74 pages of fully referenced and science-based information, and supported with a pack of 6 customisable and ready-to-use templates:

- Pandemic Risk Management Plan

- Procedure for Managing Cleaning Staff during Pandemics

- High Touch Point Cleaning Protocols

- SOP – Cleaning and Disinfecting on High Touch Points

- SOP – Coronavirus Decontamination Cleans

- COVID-Safe Cleaning Plan

Book purchase details please…

Hi Richard,

thanks for your interest in the Guide to Cleaning for COVID-19. You can purchase it on the Coronavirus page of this website

Hopefully this link will work from the comments, but if you click on the image it will take you there.

https://hpcsolutions.com.au/product/coronavirus/

thanks, Bridget